The production process of plastic packaging bags

Time:

Dec 27,2024

Mixing: Mix one or more plastic materials (such as linear polyethylene, low-density polyethylene) or additives evenly through a mixing machine.

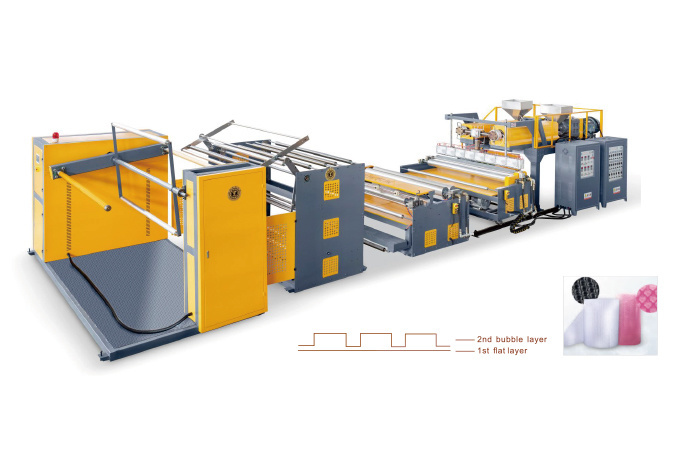

Blowing film: The mixed plastic raw materials are melted by heating and blown into a plastic film using a blown film machine. After cooling, a raw material film for making plastic bags is formed.

Printing: Printing patterns onto plastic film using an ink roller.

Sealing: Cut and seal the printed plastic film to form the desired plastic bag. In modern technology, the sealing and cutting machine can be completed in one step, which improves efficiency.

Packaging and shipping: Finally, the finished product is packaged and shipped.

Differences in production processes for different plastic packaging bags:

Extrusion method: using plastic particles such as polyethylene (PE) or polypropylene (PP), heating and melting them through an extruder, extruding them into a film, and then cutting, folding, and sealing them to make plastic bags.

Blowing film method: Molten plastic is blown into a tubular film through the extrusion port of an extruder, then expanded into a wide film, and then folded, cut, sealed, and other processes to make plastic bags.

Injection method: Inject molten plastic into a mold to cool and solidify, then take it out to make a bag, commonly used for making sealed pockets or bags.

Adhesive method: Stack different types of plastic films together, preheat and press them together to form a composite film, and then cut and seal them to make multi-layer plastic bags.

These processes can be flexibly combined and adjusted according to specific needs to meet different packaging requirements.