Analysis of LLDPE multi-layer co extrusion stretching film machine technology

Time:

Oct 12,2024

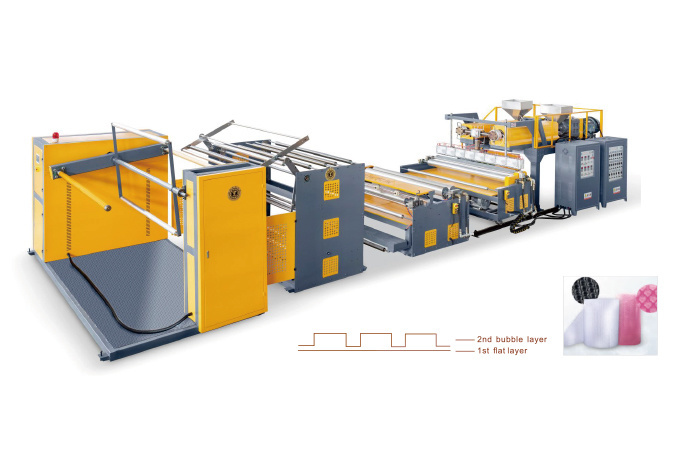

LLDPE (linear low-density polyethylene) multi-layer co extrusion stretching film machine is an important technical equipment in the plastic packaging industry, widely used in the production of packaging materials in food, medicine, electronic products and other fields. This equipment produces thin film products with high transparency, high strength, good heat sealing and barrier properties through multi-layer co extrusion technology and subsequent stretching treatment. This article will delve into the working principle, structural composition, key technical characteristics, and application value of LLDPE multi-layer co extrusion stretching film machine in the modern packaging industry.

Working principle and structural composition

The LLDPE multi-layer co extrusion stretching film machine is mainly composed of raw material feeding system, extrusion system, cooling and shaping system, stretching system, corona treatment and winding system.

Raw material feeding system: Ensure that different types of resin raw materials are accurately and evenly fed into the extruder.

Extrusion system: Using multi-layer co extrusion technology, multiple extrusion heads work simultaneously to extrude different materials of molten resin in specific proportions, forming a multi-layer structure of molten film.

Cooling and shaping system: using water or air cooling to quickly cool the molten film, allowing it to solidify initially and achieve the desired thickness and shape.

Stretching system: By using biaxial stretching technology, the film is stretched in both longitudinal and transverse directions, significantly improving its mechanical properties and dimensional stability.

Corona treatment: enhances the adhesion of the film surface, facilitating subsequent printing or composite processing.

Roll up system: neatly roll the finished film into rolls, ready for further processing or direct use.

Key technical features

Multi layer co extrusion technology: achieving precise proportioning of different materials to meet different packaging needs, such as moisture resistance, oxygen resistance, barrier properties, etc.

High precision control: Adopting advanced control systems to ensure uniform thickness of each layer, improving product quality and production efficiency.

Energy saving and efficient: Optimized heating and cooling system design reduces energy consumption and improves production efficiency.

High degree of automation: The entire process from raw material processing to finished product coiling is automated, reducing manual intervention and lowering production costs.

Application value

The film produced by LLDPE multi-layer co extrusion stretching machine is widely used in food packaging, pharmaceutical packaging, electronic component protection, agricultural covering materials and other fields. With its excellent mechanical properties, good optical properties and high barrier properties, it effectively extends the shelf life of products, reduces the use of packaging materials, and meets the requirements of environmental protection and sustainable development.