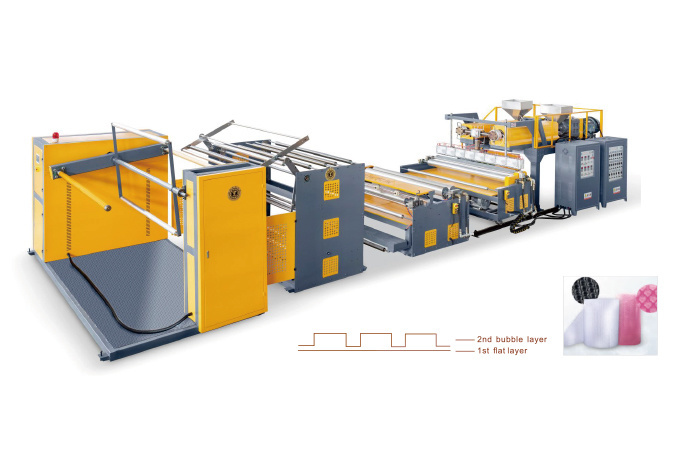

Introduction to Fully Automatic High Speed CPP/CPE Casting Film Unit

Time:

Oct 12,2024

The fully automatic high-speed CPP (unstretched polypropylene)/CPE (chlorinated polyethylene) casting film unit is a high-end equipment in the field of plastic film manufacturing, particularly suitable for producing high-quality flexible packaging materials. This unit occupies an important position in industries such as food packaging, medical supplies, and daily necessities packaging due to its high degree of automation, fast response, and flexible configuration. This article will elaborate on the structure, technical highlights, and market application prospects of the fully automatic high-speed CPP/CPE casting film unit.

Construction and Technical Highlights

Precision extrusion unit: adopting efficient single screw or twin-screw extrusion system to ensure uniform melting of raw materials and provide high-quality melt for subsequent casting.

Wide width casting die: designed with a special temperature control zone, it can accurately control the thickness of the melt and produce wide, thin, and uniform films.

Rapid cooling system: Combining water and air cooling technologies, it quickly solidifies the melt, maintaining the flatness and optical properties of the film.

Automatic thickness control: Using an online thickness gauge and feedback control system, the extrusion speed or die lip gap is automatically adjusted to ensure consistent film thickness.

High speed traction and slitting: driven by servo motors, it achieves high-speed and stable film traction and precise automatic slitting.

Comprehensive automation management: Integrating advanced control systems to achieve automated monitoring and adjustment of the entire process from raw material input to finished product output.

Market application prospects

Food packaging: CPP/CPE film has excellent heat sealing, moisture resistance, and printing adaptability, and is widely used in various types of food packaging, such as cooked food, snacks, frozen food, etc.

Medical supplies: CPE film is suitable for packaging disposable medical supplies such as protective clothing, gloves, surgical bags, etc. due to its good antibacterial properties and chemical stability.

Packaging for daily necessities and electronic products: CPP film has high transparency and glossiness, and is commonly used for packaging cosmetics, detergents, and electronic products to enhance product quality.

conclusion

The fully automatic high-speed CPP/CPE casting film unit has become an important development direction in the plastic film manufacturing industry due to its efficient production capacity, excellent film quality, and wide market applications. With the increasing demand for high-performance and environmentally friendly materials in the packaging industry, the research and application of such equipment will pay more attention to technological innovation and green environmental protection to meet the constantly changing market demands.