Overview of fully automatic high-speed PVC cling film unit technology

Time:

Oct 12,2024

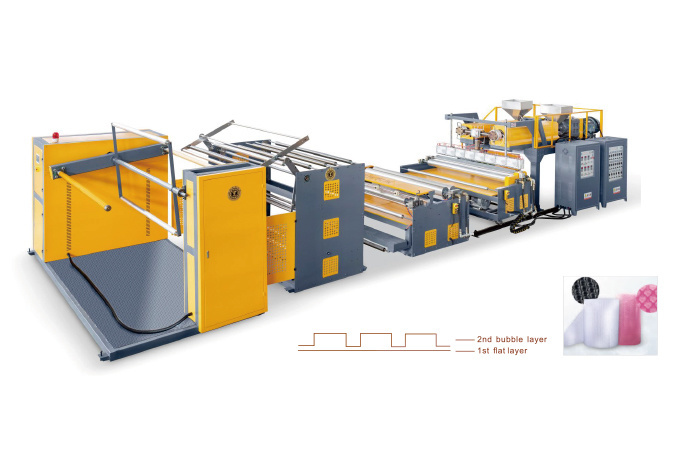

The fully automatic high-speed PVC (polyvinyl chloride) cling film unit is an advanced equipment designed for large-scale production of high-quality cling film. This unit integrates functions such as efficient extrusion, precision cooling, high-speed cutting, and automatic winding, aiming to meet the market's high demand for high transparency and strong toughness cling film. This article will provide a detailed introduction to the technical characteristics, process flow, and application advantages of the fully automatic high-speed PVC cling film unit in the field of food preservation.

Technical features

Efficient Extrusion System: Adopting a large-diameter screw design, coupled with an efficient temperature control system, to ensure the full plasticization of PVC raw materials and the production of uniform film substrates.

Precision cooling and traction: equipped with multi-stage cooling devices and precise tension control, ensuring rapid and uniform film cooling, reducing deformation, and improving transparency.

High speed cutting technology: using a servo driven automatic cutting system to achieve fast and accurate continuous cutting, improving production efficiency.

Intelligent control: Integrating PLC control system and human-machine interface to achieve real-time monitoring and adjustment of production parameters, ensuring stable product quality.

Automatic winding and packaging: After cutting, the cling film is automatically wound into a roll and packaged through an automatic packaging system, reducing manual intervention and improving automation level.

technological process

1. Raw material preparation and mixing: Mix PVC resin with other additives evenly.

2. Extrusion molding: After the mixture is heated and melted by an extruder, a thin film is formed through a flat die head.

3. Cooling and shaping: The freshly extruded film is rapidly cooled and shaped by a cooling roller.

4. Traction and cutting: The cooled film is pulled to the specified speed and automatically cut at the designated position.

5. Rolling and packaging: The cut cling film is automatically wound and finally packaged.

Application advantages

Improving food safety: PVC cling film has good sealing and moisture resistance, which can effectively extend the shelf life of food and ensure food safety.

High production efficiency: The fully automated process significantly improves production speed and output, reducing unit costs.

Environmentally friendly material selection: Although traditional PVC has environmental controversies, modern production tends to use more environmentally friendly additives and recycling technologies to reduce environmental impact.

Strong adaptability: Product specifications can be adjusted according to market demand to meet different packaging needs.